We cover all things framework in this guide to installing a composite cladding subframe.

The design, layout and construction of your cladding subframe is pivotal to a successful cladding installation. While a variety of different materials can be used to construct a cladding subframe and cladding applications can vary drastically, this guide is designed to provide you with the overall guidelines you’ll require to take into your installation. We view these guidelines as a set of rules to apply to your installation, as opposed to a rigid step-by-step guide.

This guide firstly covers the broad areas of installation, such as joist materials you can use, joist spacings and positioning, ventilation requirements and general consideration of subframe design and layout. The guide shall then provide a step-by-step instruction on how to install our own composite joists to form your cladding subframe.

Use The Appropriate Joist Material

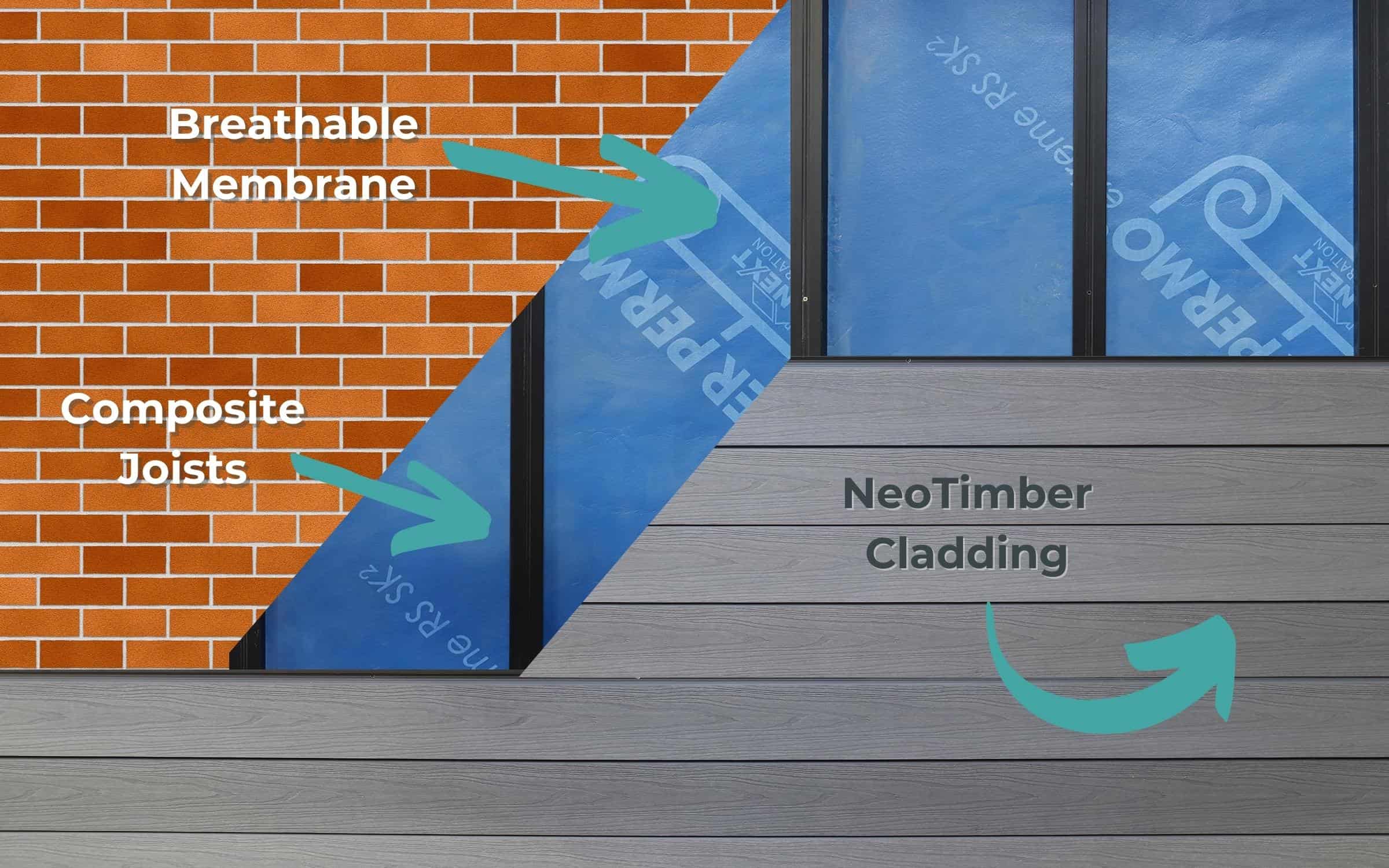

We provide a long-life, lightweight subframe solution for our cladding boards: our NeoTimber® Composite Joist (40mm x 59mm x 3600mm). It is recommended (but not a necessary requirement) that you use this solution. Alternative joists come in the form of timber or aluminium. If compliant with building regulations, then both materials can be used to install NeoTimber® cladding.

Joist Spacings & Positioning

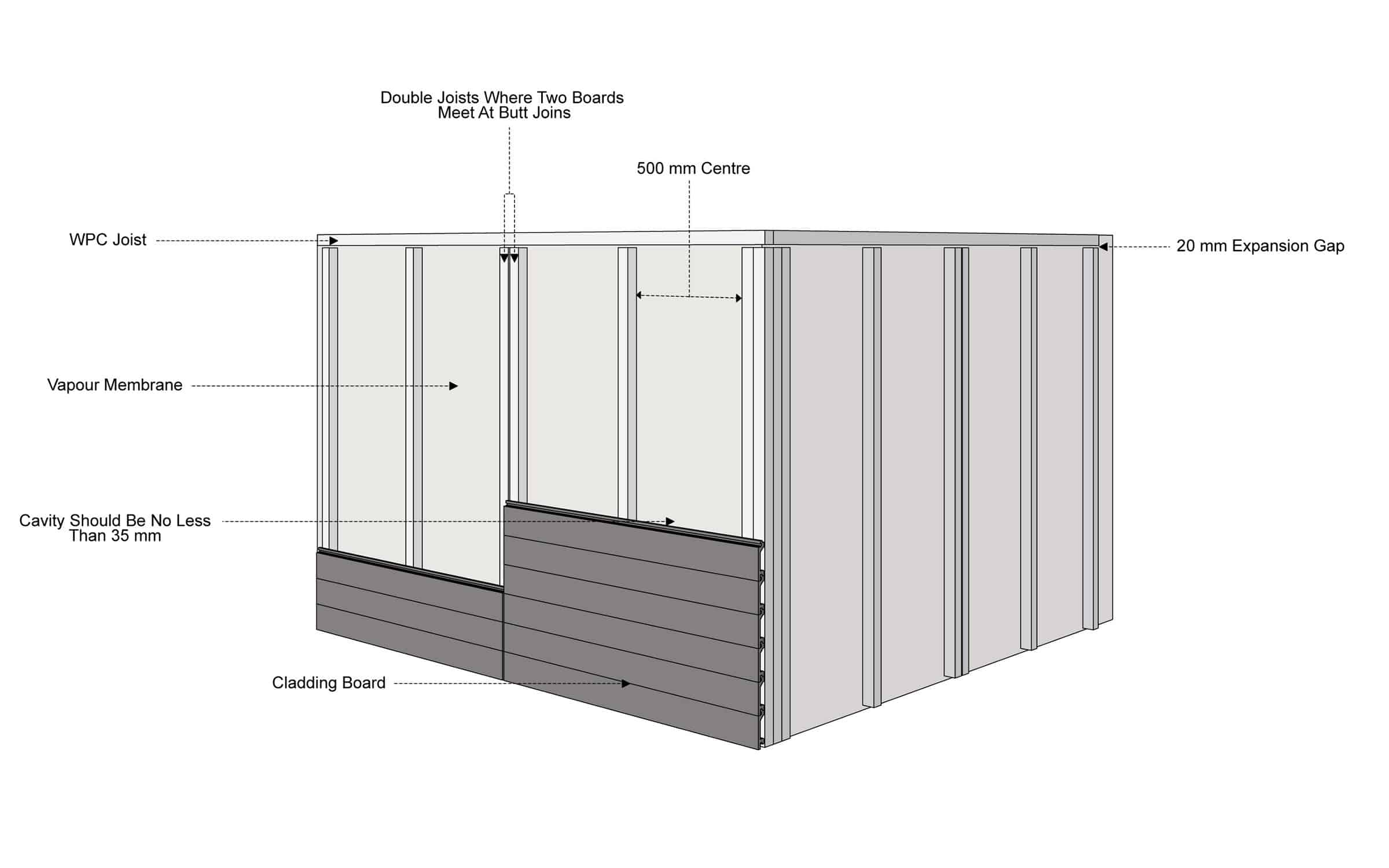

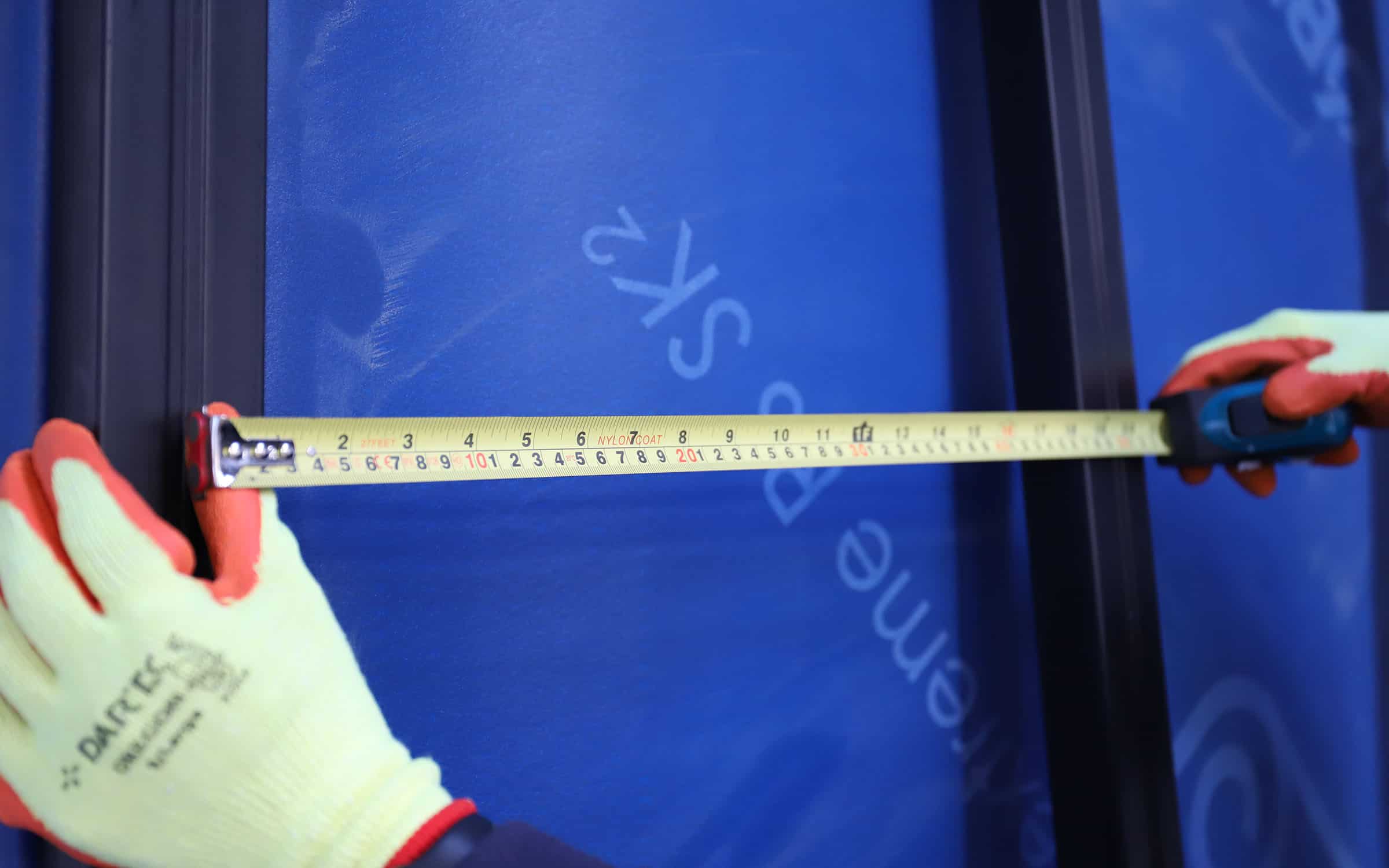

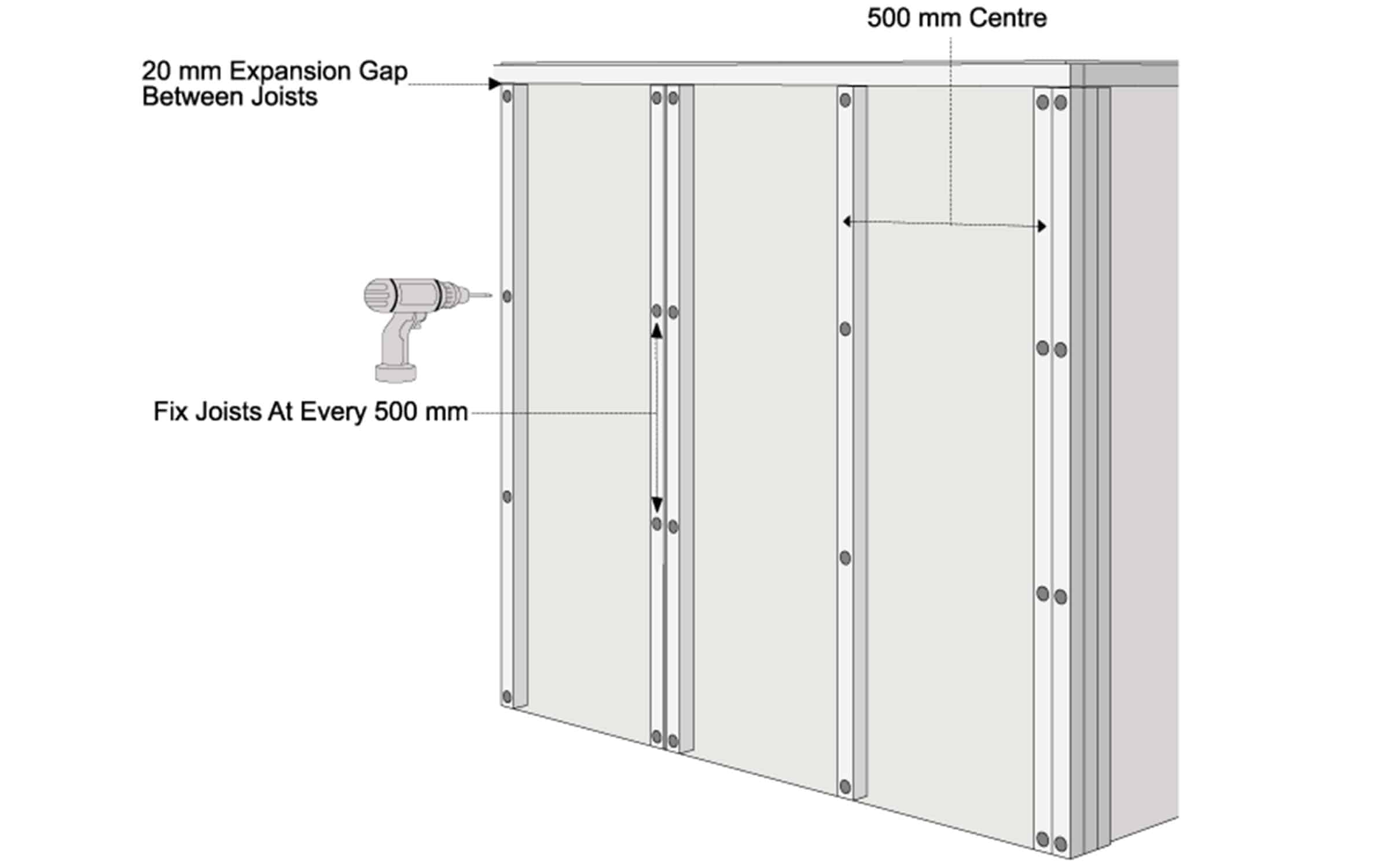

Joist spacings should sit at no wider than 500mm, regardless of the type of baton you will be installing your NeoTimber® cladding onto. In high wind load areas, we suggest narrowing joist centres to 400mm. Spacings of 20mm between adjoining joists must be observed to account for expansion and contraction of the subframe material.

Ventilation Requirements

Allow a minimum of 35mm space beneath the cladding boards to ensure adequate airflow for the cladding system – hence why we recommend that a joist with a minimum thickness of 35mm should be used. There should also be a continuous 15mm gap left at the top and the bottom of the cladding system to ensure adequate ventilation. Ventilation is a key factor in removing moisture from the material, which in turn ensures the long-life of NeoTimber® cladding products.

Subframe Design & Layout

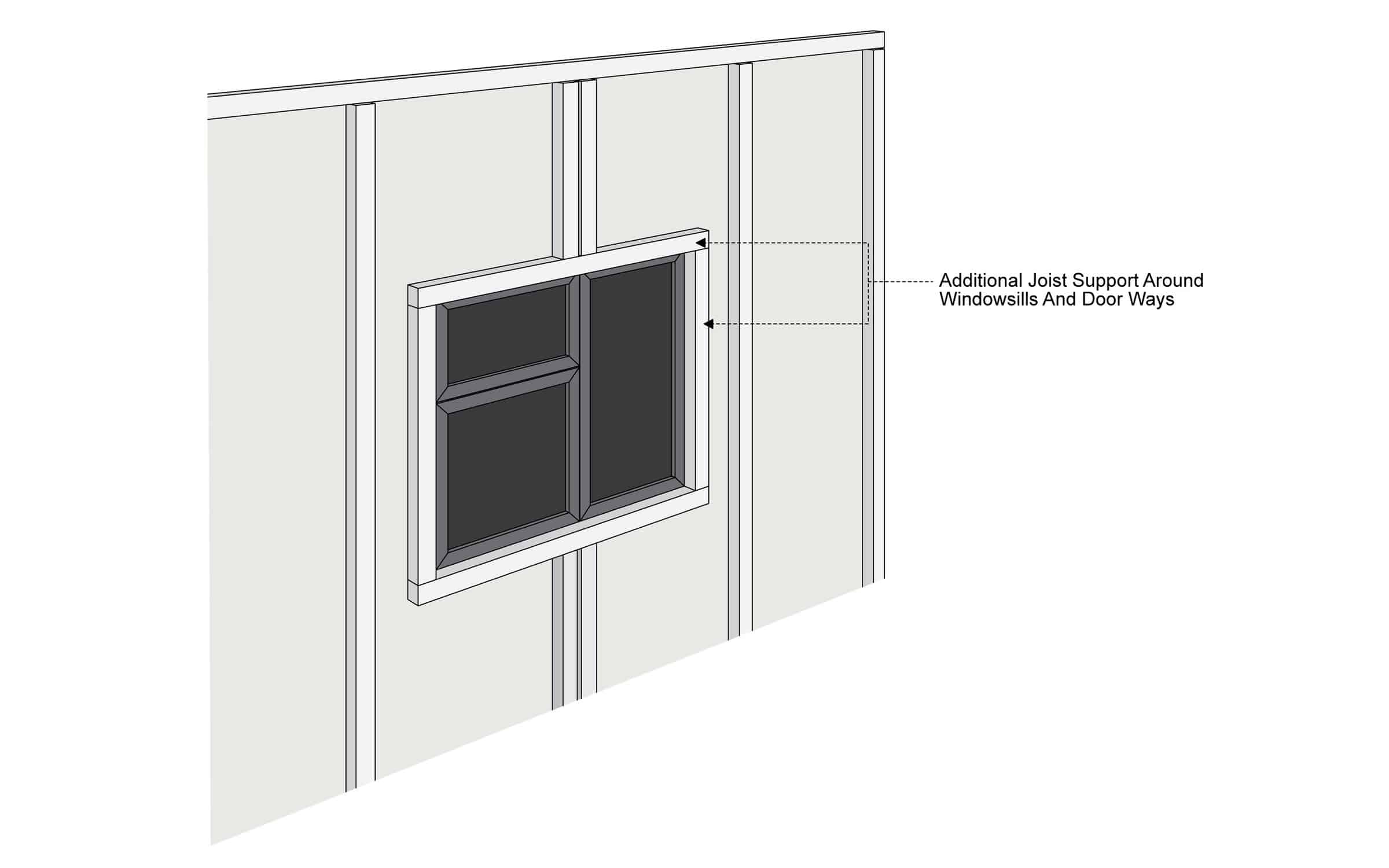

Plotting the layout of your battens will ensure that you provide adequate support to your composite cladding boards. Consider the overall design of your cladding section prior to installation. Special consideration should be taken into account for the following:

- Consider your joist layout in relation to the laying pattern of your cladding boards. Your joists should, in most cases, run adjacent to the direction of your cladding boards. NeoTimber® cladding boards can be installed in a vertical or horizontal direction.

- Consideration of where you expect cladding boards to meet at butt-ends. Double joisting is required in areas where two cladding boards are expected to meet at butt-ends.

- A consideration of features of your wall. Ensure adequate batten support is installed around windowsills, door openings, guttering and soffits. Refer to the illustration for an example of a typical joist layout.

3-Step Guide To The Fixing Of Wall Joists To Form Your Composite Cladding Subframe

For the sake of the installation guide, we outline a NeoTimber® Composite Joist installation to depict a typical cladding subframe installation. The principals outlined in the guide will apply to any cladding subframe material, regardless of the joist/baton solution used. This 3-step process should therefore be followed when fixing your cladding joists to your wall.

Step 1. Begin Installing Joists

Beginning from a corner or edge of the face of the wall, work inwards and space your joists evenly at 500mm centres. If a vapour barrier is being installed, ensure that this is positioned and fixed securely to the existing wall prior to your joists being fixed.

To allow for adequate ventilation of the cladding system, a gap of at least 15mm should be observed between the bottom of your joist(s) and the ground. This allows the adequate movement of airflow beneath the cladding system.

Step 2. Allow For Expansion Gaps

Ensure spacings of 20mm are observed where joist ends meet; this is to allow for adequate expansion and contraction of the material.

Step 3. Fix Joists Securely To The Wall

When fixing the NeoTimber® composite joist securely to the wall, each joist should be fixed at 500mm intervals along its length. We recommend using countersunk A4 stainless steel screws to securely fix your battens to the wall. Pre-drill the material prior to fixing it down to avoid the material cracking when fixed. Ensure joists are laid level against the wall. Packers can be used to level-off any inconsistency in the level of the wall.

Need Further Support or Advice?

If you’ve still got questions that have not been answered here, or you would like additional advice,

support or assistance then please give one of our friendly experts a call and we’ll be happy to help.

Just give us a call on 01530 382 180.