For installations on uneven ground, opt for installing plastic lumber.

Consisting of a plastic joist and post product – this plastic lumber subframe is effective in areas with sloped and uneven ground, and represents a truly long-life, moisture resistant solution formed entirely from recycled plastic material.

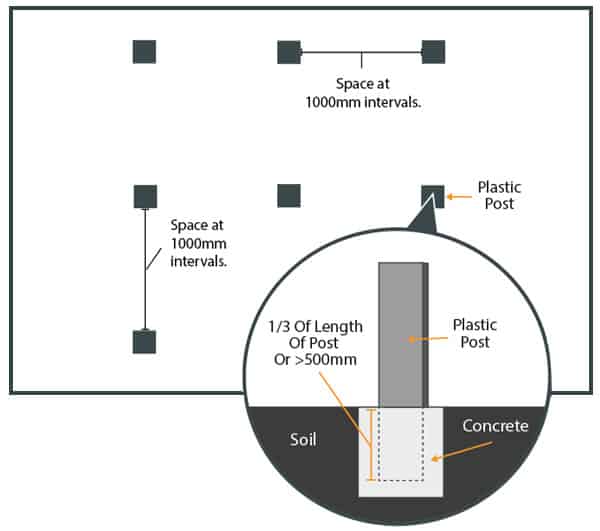

1. Lay Your Post Network And Secure Into Place

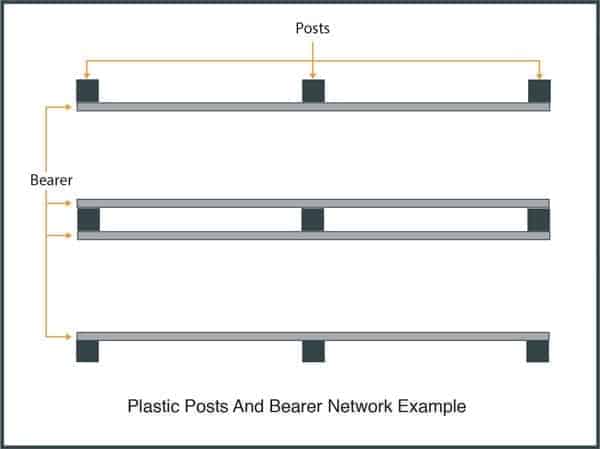

Once your area is clearly outlined, mark a grid-layout and evenly lay your plastic post network. Space the posts at 1,000mm intervals. This is in keeping with the maximum support span of the large plastic joist that will be used to form your cross-bearer and joist network.

Fix the posts to your base by forming a hole and cementing them into the ground. A third of the length of the post (or at least 500mm) should be secured under the surface of your base. Ensure the posts remain in an upright position as the concrete sets and that the tops of the posts are level with one another.

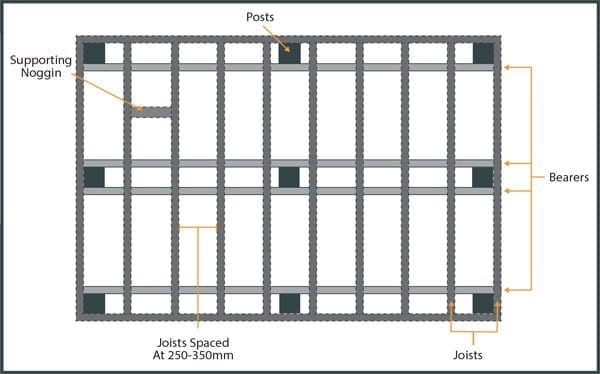

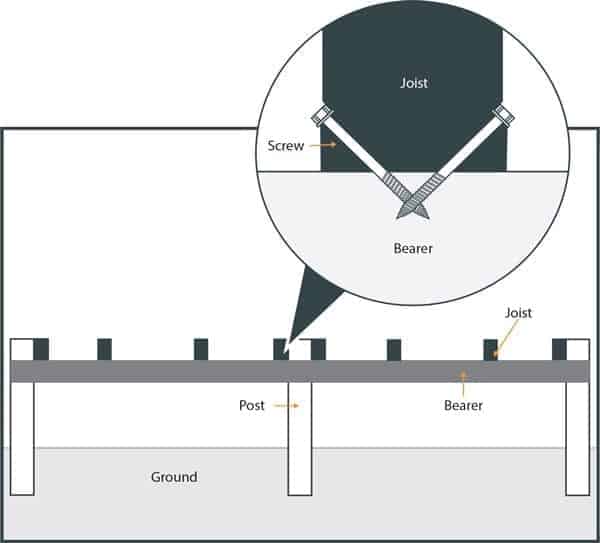

2. Laying Plastic Joists To Form A Bearer Network

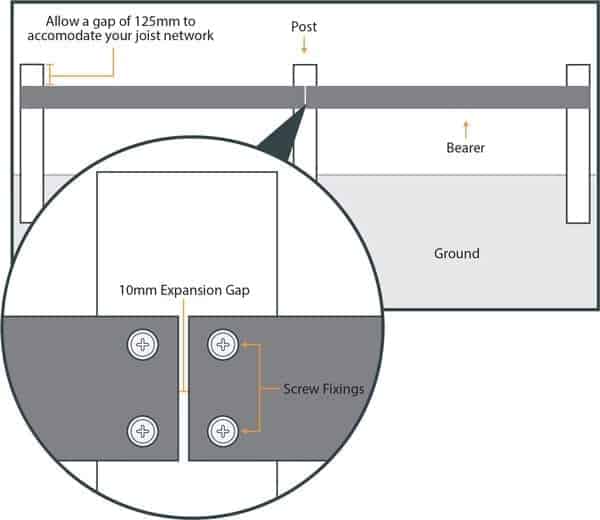

Form a network of cross-bearers along the length of posts with the large plastic joist, providing a base of structural support for your joist network. When fixing the bearers to the posts, a gap of 125mm should be left above the bearer in order to accommodate for the thickness of the joist.

3. Securing Bearers At Joins

Joining bearers must be supported by a post and an expansion gap of 10mm must be observed. Ensure that joins in joists are supported by double bearers. Use 2 x 6-10mm single thread screws at every intersection between a bearer and post to fix securely. Pre-drill the material with an oversized pilot hole (approximately 3mm).