The key ingredient to a successful composite decking project is preparation.

We believe that certain elements of a composite decking install should be covered prior to embarking on the installation of your NeoTimber deck boards and ancillary products. This section shall cover each of those key elements from the planning phases, to tips on handling your deck boards, through to guidance on the recommended cutting equipment for our composite material.

We suggest that you take the time to consider the areas below, ensuring you are fully equipped to create your ideal decking project.

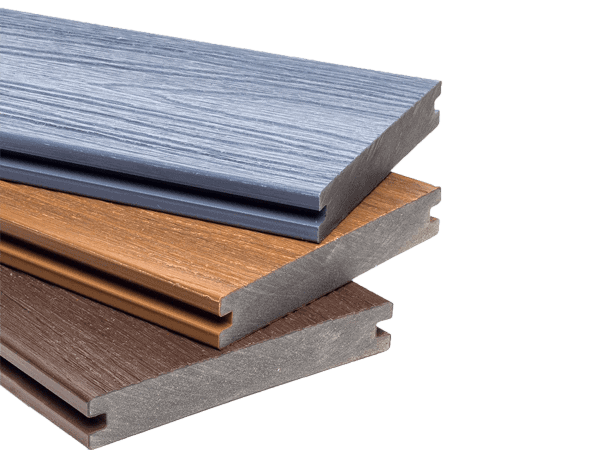

Colour Characteristics:

Traditional Composite Decking

Our traditional composite deck boards (NeoTimber Essential and Classic Ranges) shall undergo a level of weathering (lightening-up) within the opening 3-6 months of installation. This initial weathering process is a result of the boards reacting to UV rays. Once this process has taken place, the rate of change will be nominal.

You may also notice a colour contrast between the skirting/corner trims and your deck boards especially if you are installing the boards wood-grain side up. Once the boards find their weathered colour-tone, the contrast will be more subtle.

Capped Composite Decking

Our capped composite deck boards (NeoTimber Advanced and Deluxe Ranges) come equipped with a protective polymer shell, ensuring high UV and fade resistance. They have been designed to have a high quality dual-toned appearance. The colour tone of these boards shall slightly vary from board-to-board in order to mimic a more authentic, real woodgrain finish. Consideration of this should be taken upon installation.

Subframe Options:

Our decking system should not be installed without a framework in place. All deck boards must be installed directly onto a subframe of composite, plastic, timber or metal joists. Allow a minimum of 35mm space beneath the decking subframe to ensure adequate airflow beneath the structure.

Temperature Considerations:

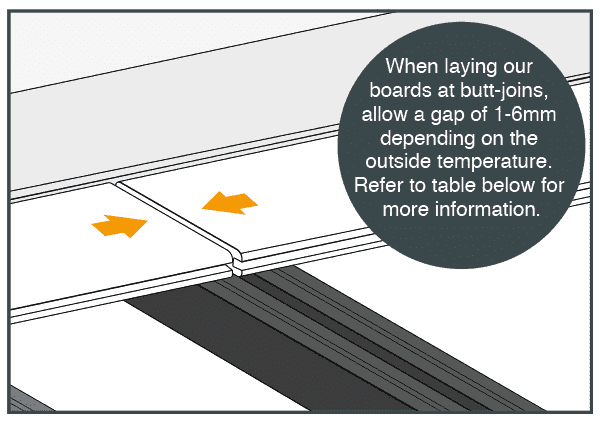

Composite decking naturally contracts and expands in varying temperatures. Our FastClip installation system allows for adequate side-to-side spacing to manage these effects. However, it is advised that suitable gaps should be maintained at end-to-end joins as outlined in adjacent illustration and table below.

| TEMPERATURE GUIDANCE TABLE | |

|---|---|

| Outside Temperature | End-To-End Gap |

| Below 4°C | 6 mm |

| Between 4°C – 25°C | 3 mm |

| 26°C or over | 1 mm |