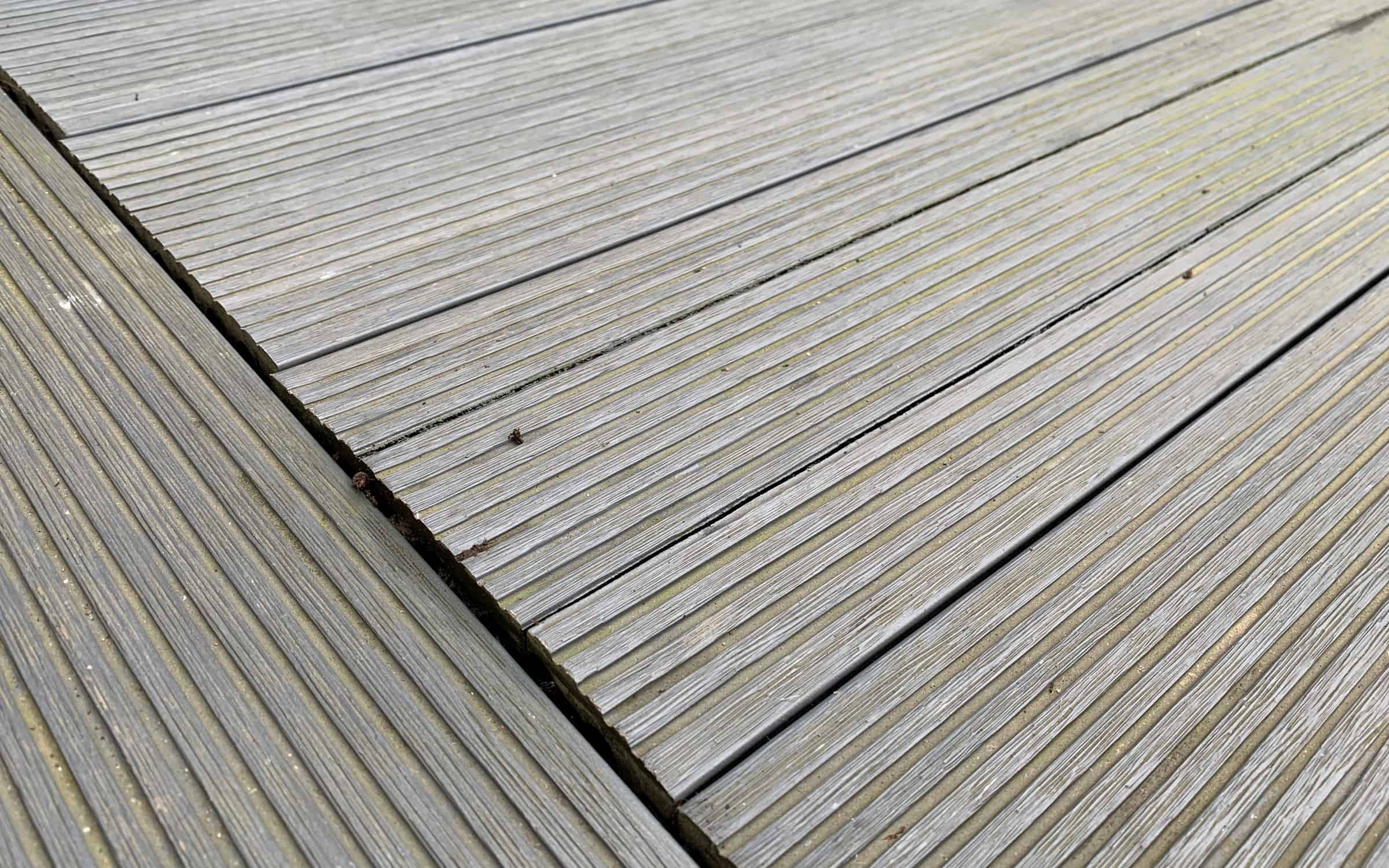

If you find your composite decking cracking, it’s usually because it’s been fitted incorrectly. Here’s how to prevent it…

Though a far more common sight on timber, composite decking cracking is an issue that tends to emerge only after it has been installed and had time to sit. There are several reasons as to why this occurs. With some brands, it may be down to poorly designed fixings or poor-quality materials. Though NeoTimber’s composite boards combine high quality materials with a dedicated and attentive construction process, there are still many contributing factors that can cause cracking in composite decking. The most common? Poor – or incorrect – installation. Let’s look at some common mistakes and investigate the primary causes of cracking in composite decking…

Not Pre-Drilling The Material

NeoTimber® decking boards are designed to be fitted using our custom decking clips. Our discreet fixings have been engineered to fix into the joists and clip onto the groove along the length of the board, holding it snugly but giving the boards room to expand and contract. These clips should be used for all fixings, but not for any final edges or trims (such as decking edging).

In areas where you do need to face fix the boards using NeoTimber’s decking screws, pilot holes of no less than 3mm should be drilled in each case. Doing so will prevent cracking, as it will give the boards more space to expand and contract around the screws during temperature fluctuations.

Fixing All Boards With Screws

At NeoTimber®, we recognise that there are professionals and experienced DIY’ers who have been fitting decking for years. To some, it may seem that using clips instead of just drilling screws into the decking joists seems like an unnecessarily complicated method of fixing. However, our proprietary fixing clips are purpose-built to allow the composite deck boards to expand and contract with changes in the temperature.

Because composite boards are 30% plastic, they expand and contract to a greater degree than traditional timber deck boards. This means that the composite material can press against a screw as it expands, causing it to warp, bend, and crack. By pinning the boards down, they simply have nowhere to go as they expand, and they tend to suffer greatly for it.

Not Fixing Boards At Recommended Joist Centres

When first installing your composite decking, your joist centres should be between 250mm and 350mm. While these joist spacings are tighter than those commonly associated with timber, it’s important to remember that the plastic element provides the boards with more flex than a traditional timber product. So, it pays to ensure a narrower joist support beneath the deck boards.

Failure to install sufficient joists will just put undue stress onto your boards, and it will lead to bowing and warping of the boards over time. It can also ultimately lead to cracking of the boards where they are not supported correctly.

Ensure That You Have The Correct Board For Your Needs

It’s important to do your research about which board is most appropriate for the specifications of your space. Our hollow boards, for instance, will naturally have a lower weight bearing capacity when compared to our solid solutions. Our solid Classic and Deluxe deck boards are engineered specifically to support more weight, making them ideal for projects that incorporate hot tubs or have a high level of footfall.

The weight bearing qualities must be taken into account when specifying the right deck board for your project, as failure to do this can be a sure-fire way of cracking your composite deck boards, or worse: compromising the structural integrity of the entire deck floor. For more information on choosing the right deck board for your project, check out our NeoTimber® composite decking buying guide.

Incorrect Product Handling

One common reason installers discover cracking of the boards is due to incorrect handling at the storage and installation phase of the project. Every care is taken to ship and dispatch boards to you in good condition; we check each board as they are received by our warehouse team, and again before they are delivered to you on site.

Once they are in your care, decking boards should be covered while stored. They should be stored out of the way of walkways and thoroughfares to ensure no damage is caused to the boards prior to installation. Lifting the boards off ground level whilst storing the product is also key to ensure any damage is avoided.

Need Further Support or Advice?

If you’ve still got questions that have not been answered here, or you would like additional advice,

support or assistance then please give one of our friendly experts a call and we’ll be happy to help.

Just give us a call on 01530 382 180.