Let’s Teach You How to Master Installing Composite Decking

100% Mistake Free

So you’ve heard of this exciting new timber decking alternative – composite decking – and think ‘I bet I can install this just like I installed my old decking’. We hate to break it to you, but this is not the case. Installing composite decking yourself is far from difficult, but it demands a level of product knowledge that NeoTimber® is eager to share with you.

From exploring expansion and contraction differences to sharing our unique subframe guides, we hope to give you all of the tools you need to avoid making costly and unsightly mistakes when installing composite decking.

Just like any other project, installing composite decking requires extra preparation and planning to avoid all sorts of issues in the future. From warping to collapsing altogether, these problems are ones that won’t be covered under your 25 year warranty if our manufacturer guidelines aren’t followed. And nobody wants that, do they? After all, you didn’t spend all of that money just to have the look and strength of your new decking compromised only a few months in.

Lucky for you, all you need to do is stay mindful of these common mistakes when installing composite decking. Let’s dive into our ‘dirty dozen’ – a list of twelve installation mistakes we see on a regular basis here at NeoTimber®.

1

Insufficient Expansion Gaps Between Butt-Ends Of Decking

Composite decking is unique. Unlike regular timber, it’s comprised of wood fibres and recycled plastic to create robust, eco-friendly boards. However, due to the inclusion of recycled plastic elements, your composite deck boards will expand and contract in ways regular timber decking doesn’t. Don’t worry, this isn’t a big deal – it just means that you have to put in a little more work to accommodate for this difference.

This is why we ask that you carefully measure the required distance (*1mm if the temperature is over 26 C, 3mm if 4 C – 25 C, 6mm if below 4 C) when installing composite decking, specifically when butting them end on. This will create the perfect expansion gap to completely prevent the warping and twisting of your boards later on down the line.

2

Insufficient Ventilation Underneath The Deck

Because composite decking contains cellulose fibres – specifically from the recycled wood used in its composition – it’s impossible to stop your boards from absorbing a small amount of moisture. That isn’t to say, however, that they’re going to rot away like traditional timber might. Rotting only occurs when wood is exposed to extended periods of moisture without having time to dry properly.

So, we strongly recommend leaving a minimum gap of 35mm between your base, concrete, slab or turf, and the underside of your deck boards when installing composite decking to ensure sufficient airflow. In doing so, you’ll give your composite timber joists and composite deck boards room to breathe, allowing them to drain and dry with no complaints.

3Using A Poor Quality, Substandard Subframe Material

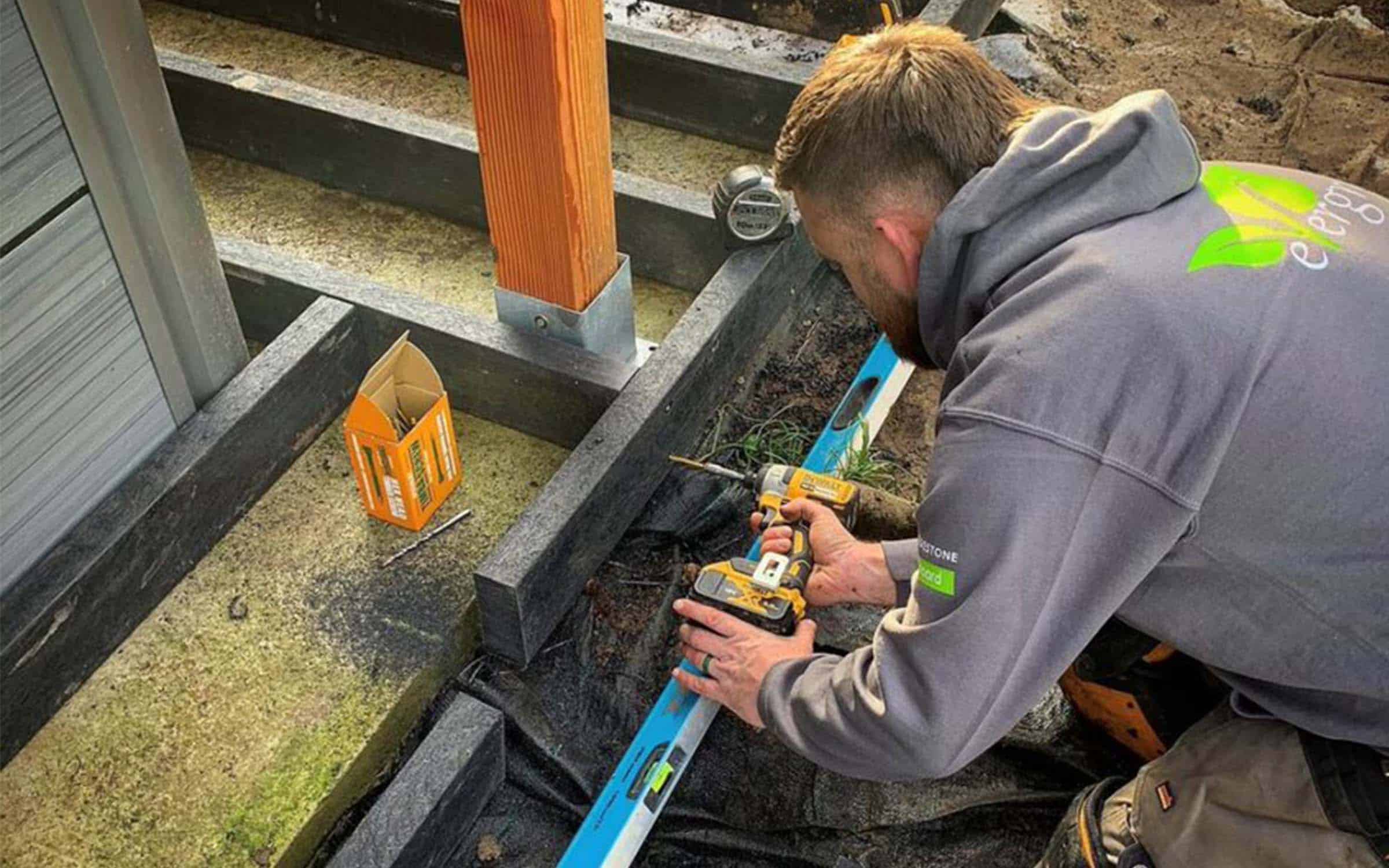

As with everything, there are okay-ish subframes, and then there are great subframes. Unless your old subframe was installed with the utmost care and consideration, chances are your joists are way past their prime. This is often caused by standing water and general erosion – elements that you may think are out of your control.

Composite decking, however, is different to timber, in that it requires significantly more support. Five joists alone just won’t cut it. You’ll either need to upgrade your existing subframe by installing additional joists, replace old joists with new timber joists, or install an entirely composite-based subframe. And, if you happen to be installing composite decking in an area prone to flooding, a subframe comprised of plastic lumber would be the perfect, rot-free solution. Whatever you choose, NeoTimber® is here to support you.

4Installing Onto A Substandard, Pre-Existing Timber Subframe

A wise man once said, “only a fool builds his house upon sand”. Your decking is only as strong as its foundations, so it’s important to get your base right before you start installing your composite decking. So, if you take one thing away from this, let it be this – carefully choose the right material for your subframe!

If building a roof terrace or balcony, a steel subframe would be a preferable option thanks for its unique self-anchoring properties. If you’re building close to water or a high water table, however, choose plastic lumber over timber to avoid rotting risks. Only use seasoned wood if building a timber subframe; it’s the only way to ensure it can handle high levels of footfall. We know you’re not silly, but these little unsaid titbits make for invaluable advice when installing composite decking.

5Installing On Wider Joist Centres

Though you might think it’s practical to reuse your existing timber subframe when installing composite decking, we’d beg to differ. Typically, timber decks have a joist centre of about 500mm, whereas a composite deck joist centre should be placed 250 – 350mm apart. This is simply because of material disparity between timber and composite decking boards.

Timber has a lower degree of flex compared to composite’s recycled plastic and timber fibre blend, meaning a little extra support is needed to keep it healthy and sitting comfortably. But only a bit of additional support for an incredible boost to strength and longevity? Not a bad trade if you ask us.

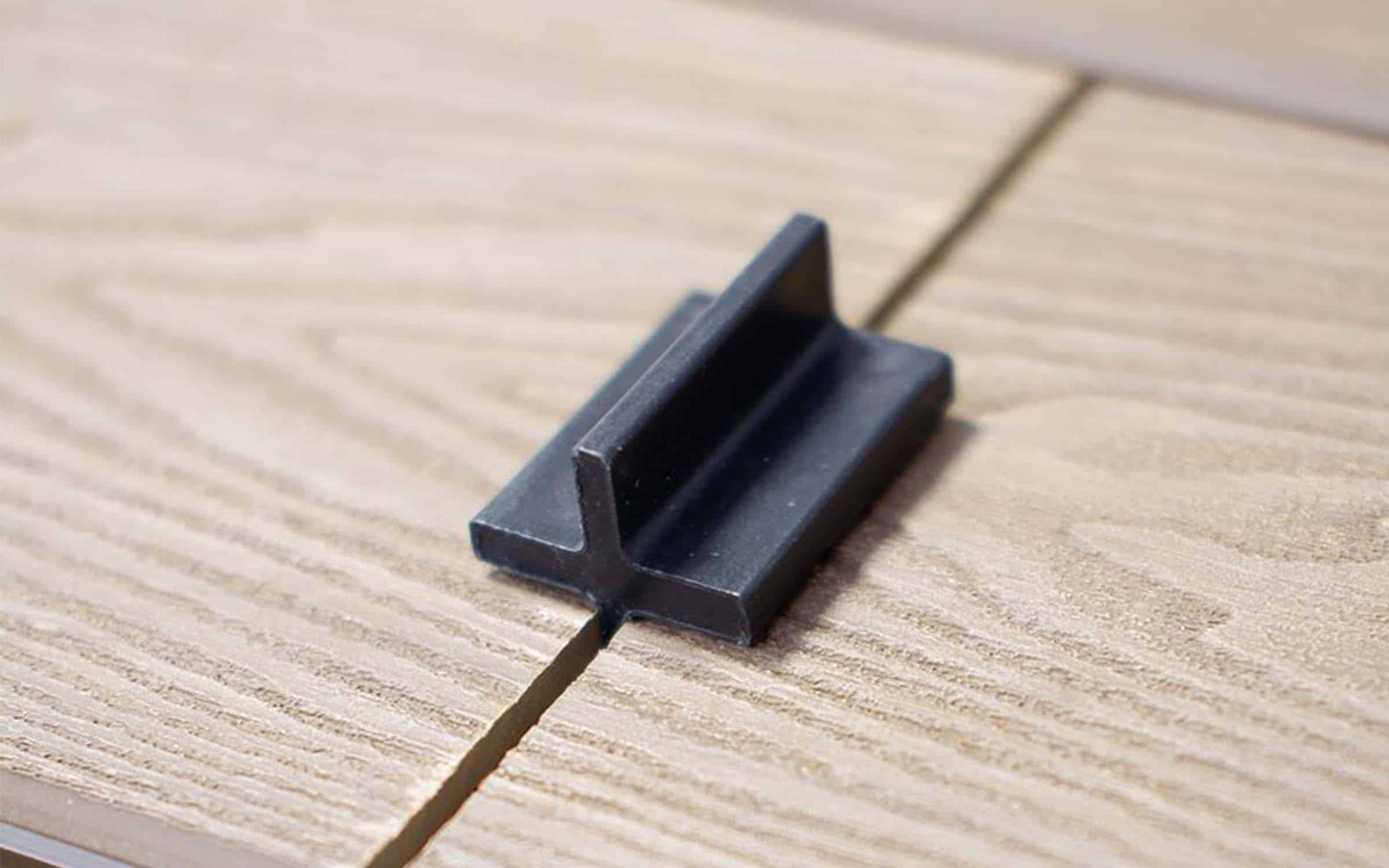

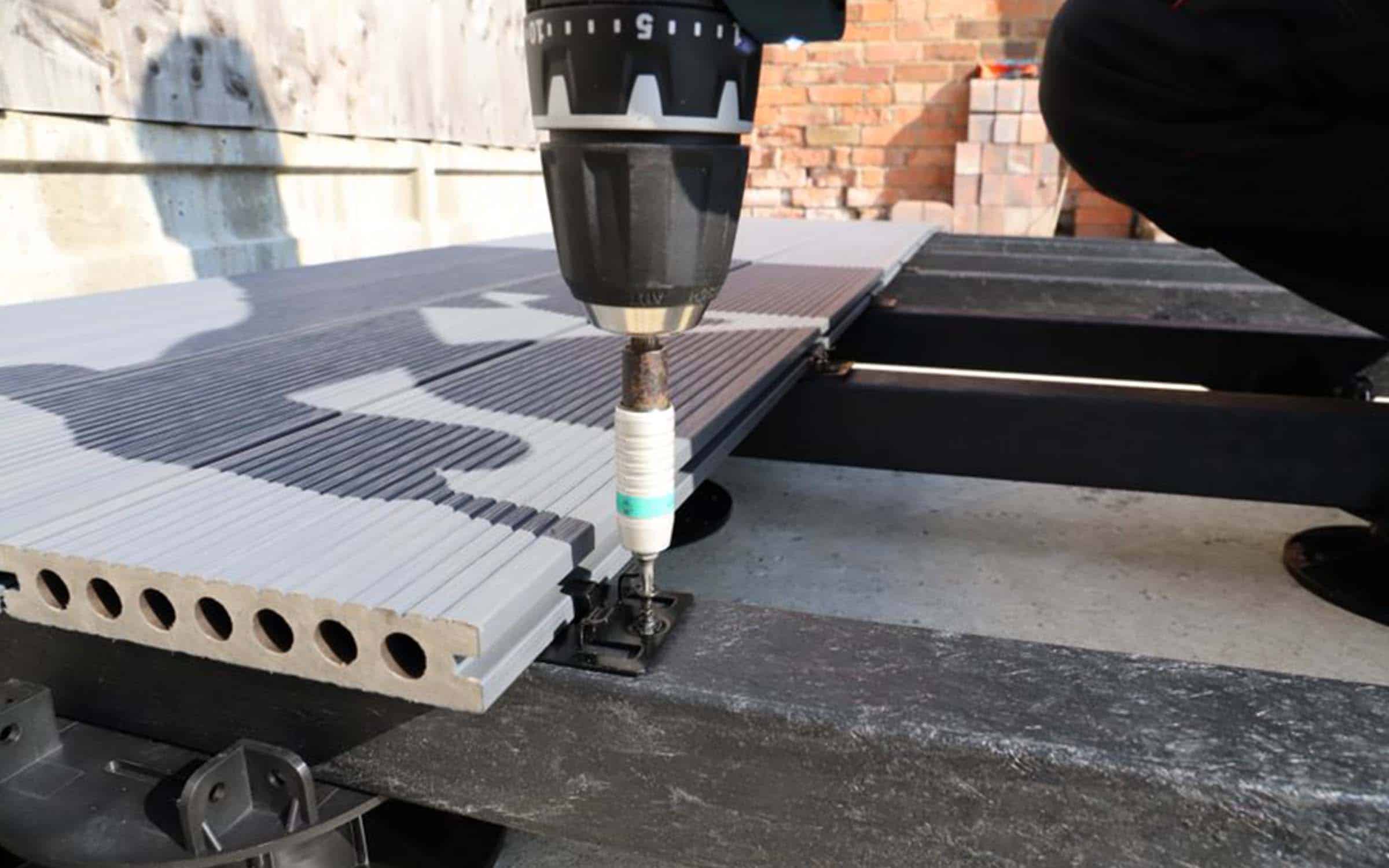

6Using An Alternative Supplier’s Composite Decking Clips

It’s tempting to think you know best, especially when it comes to doing something you’ve done before. But trust us, composite decking boards behave differently to wood. So, what works for wood just won’t work with composite. Thankfully, since we’re designers, manufacturers and suppliers of our own patented products, NeoTimber® has created products that effortlessly synergise with one another.

We want to be your single point of contact for installing composite decking, and have therefore developed a product range that specifically caters to your every need. In this instance, our decking clips work best with our decking, simply because they’re designed to do just that. Just like our boards, they’re able to flex and expand as the decking changes shape. Gone are the days of decking inconsistency. Finally!

8Not Treating Cut Ends Of Timber Joists

It should stand to reason that any timber you are using to build a decking subframe should be treated properly. Top, bottom, sides and ends. Subframes built for installing composite decking are no exception. Not fully treating your timber is a simple, common mistake we encounter a lot here at NeoTimber® HQ. The main reason ends are missed is simply because it’s easier to paint joists when they’re suspended on the posts; you can paint top and bottom without having to wait for them to try. Sadly, this means that the exposed ends butted against a wall or fence are often neglected.

Please don't forget them! They're just as important to keeping your subframe safe as their sibling sides, so be sure to give them the same love. It might feel like a hassle at the time, but we promise it'll be worth your while in the long run.

9Not Installing Double Joists Where Two Joining Boards Meet

A strong base is important when laying your decking. In the case of a long deck, one which exceeds 3.6m, a double joist should be installed when deck boards butt together. It is imperative that all joins are given extra support to make sure planks do not split or slip. Install deck boards with an appropriate expansion gap (as seen in number 1), according to the temperature at the time of fitting.

10Using Methods From Alternative Suppliers

If you have worked with composite timber before, it may be tempting to use the fixing method recommended by the supplier you last worked with. However, not all composites are made equal. Each composite has a slightly different composition which, unsurprisingly, means they require a different approach.

We have worked tirelessly with our design team, professional installers, and customers to understand the tolerances of NeoTimber® composite boards to create an installation guide which best befits our products. After all, you are our top priority, and receiving a composite decking that's built to last is the very least you deserve.

11Not Allowing For Adequate Drainage Slope

Any handyman with a spirit level might believe that perfect levelling is the way forward when installing composite decking. Little do they know that doing so could actually prevent your decking from draining properly. The result? Standing water that could very well eat away at the health of your composite decking.

So, to ensure proper drainage, you should allow a fall of 1% (1:100). In practice, this means that your deck should slope slightly (away from your house) by 10 mm for every one metre of length. This unnoticeable difference won't interfere with your deck's overall appearance, but will enable water to drain away easily and take the risk of rot and slippery surfaces with it.

12Specifying A Product Not Suited For The Setting

Within the NeoTimber® composite decking family, there are four distinct products, and each one has its own traits and quirks. While our Essential and Advanced products are partially hollow to make for straightforward installation. , our Classic and Deluxe boards are solid boards that prioritise strength. But why tell you this? Well, it's important to decide what you want to get out of your deck. Wanting a nice space for you and your family to relax in? Go hollow. Looking to build a terrace for your hot tub? Choose solid.

It might seem self explanatory, but it's not uncommon for homeowners to choose from our Essential and Advanced range, only to learn that hollow boards are far from suitable for their intended purpose. Make the distinction first to avoid disappointment later, and you'll be fine.

Need Further Support or Advice?

If you’ve still got questions that have not been answered here, or you would like additional advice,

support or assistance then please give one of our friendly experts a call and we’ll be happy to help.

Just give us a call on 01530 382 180.