There are many alternatives to timber decking. In this article, we look at the core advantages of composite decking vs uPVC decking.

In a world of uncertainty, with pandemics still threatening our way of life, the last thing we want to be doing is spending our precious weekends stripping and staining the decking. Quite the opposite, we want to spend our time kicking back and enjoying our outdoor space in the sunshine.

There are many alternatives to timber decking, including paving and stone. But the answer to finding a replacement for your rotting decking may be simpler than you think. We all love the look and feel of a timber deck, but the truth is, life’s just too short to be constantly maintaining it. In this article, we look at the advantages of composite decking over uPVC decking.

What are the Main Composite Decking Advantages When Compared with uPVC Plastic Decking?

In recent times, artificial alternatives to timber decking have entered the market. Composite decking and uPVC both in theory offer a minimum maintenance alternative to timber decking. The question is, which is best?

Your final decision will be guided by preference and budget. Both materials have advantages, both composite decking and uPVC decking are longer lasting than timber decking. UPVC decking is made from 100% plastic which means there is no chance of rotting as it cannot absorb moisture.

The problem with plastic decking is that it looks, plastic. Plastic decking is made cheaply and is almost entirely hollow. This reduces strength and offers virtually no grip when it becomes wet. This makes plastic decking extremely slippery and dangerous for young children and the elderly.

The main difference between uPVC and composite decking is the level of water absorption. Typically, composite decking will absorb less moisture than timber. Plastic decking won’t absorb any liquid.

Wood polymer composite, or WPC decking, is manufactured from recycled plastic and reused wood fibre. These are bound together to produce a high-performing product with an authentic timber-like finish.

The Core Advantages of Composite Decking over uPVC Decking.

At NeoTimber® we fully believe that our composite decking outstrips plastic for sheer look, feel, performance and longevity. Below, we have outlined how we came to this conclusion:

Looks.

One of the main reasons customers purchase composite decking over uPVC is because of its superior finish. Composite decking offers a more natural look and feel. This is primarily because of the wood fibres that make up the composite material, but also because we have designed it to have varying tones and shades to emulate real wood.

Available in solid lengths or partially hollowed-out, it’s doubled-sided with a deep woodgrain effect on one side, on the reverse it has a grooved pattern.

Longevity.

Both plastic decking and composite decking have a significant lifespan compared to treated wood. The rigours of winter with frost damage, standing water, and long periods of exposure to cold weather can cause timber decking to rot.

Both plastic and composite decking perform well, in resisting natural weather erosion. Plastic has an entirely impermeable surface that completely resists frost. However, like all plastics, long exposure to extreme temperatures will ultimately result in the plastic becoming weak. Plastic is brittle and does not respond well to consistent expansion and contraction which will occur naturally.

Composite decking on the other hand is designed to flex. Engineered to be installed with gaps between, the boards are designed to expand and contract with the weather. This is made possible through the wood fibres and plastic polymers combining to create a fusion of the natural and man-made materials inhaling and exhaling heat independently.

There is no such thing as a fully slip-resistant deck. However, composite decking does have a higher slip resistance when compared to plastic decking. Plastic decking tends to have a very simplistic repeating woodgrain pattern. The grooves are not usually very deep and so offer very little in the way of grip. This can be hazardous in high-traffic areas, especially to the very young, infirm, and elderly people.

NeoTimber’s composite decking boards have a deeper woodgrain design, combined with a highly textured wood effect creates a surface that better displaces water, providing you with better grip. This is due to the timber element in composite decking. Slip resistance is increased further when opting for the grooved side.

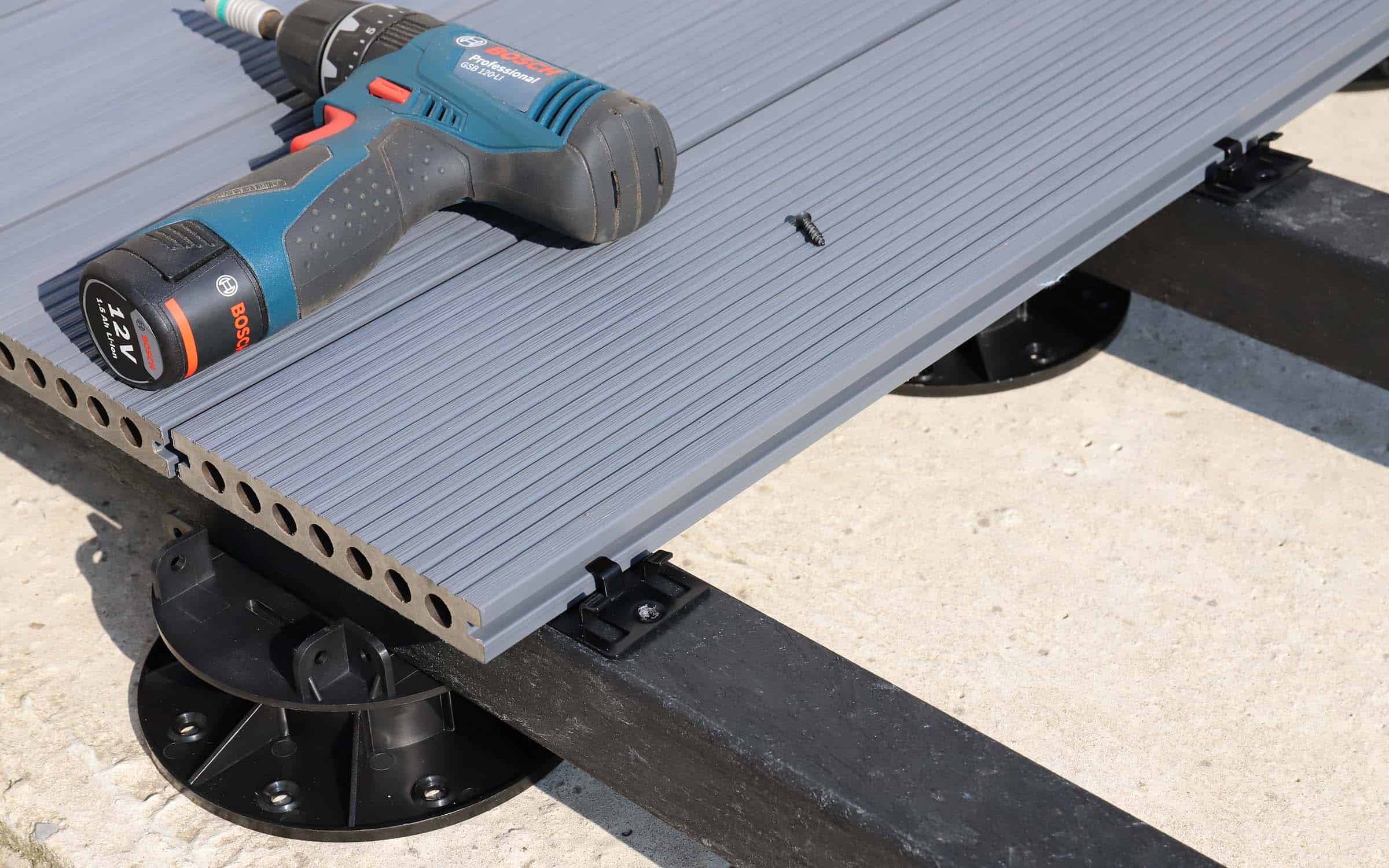

Installing a deck can sometimes be awkward. Aligning boards with even spacing is tricky. To speed the whole process up for you, NeoTimber® have created a fixing solution that is much easier to work with.

Plastic decking is installed by aligning interlocking parts that ‘jigsaw’ together. These can be quite brittle and not overly flexible to work with, meaning they can break.

NeoTimber’s discreet clips allow for expansion and contraction to happen without your boards warping or bowing. They also aid with creating even spacing when installing.

Both plastic decking and composite decking are low maintenance when compared to timber. Artificial decking never needs stripping, staining, or painting. Composite decking has that authentic feel of timber deck, but you never need to repaint it.

The only maintenance necessary for artificial decking is to clean it thoroughly after the winter. Using a jet wash is an ideal way to clean your decking. However, you should use a fan attachment when spraying the decking to prevent damaging the surface of the board. This is even true when jet washing timber decking as holding the nozzle too close to the board can cause the board to splinter.

Timber subframes are cheap to source and relatively easy to build. However, all wood, however carefully installed is ultimately prone to rot. Plastic lumber is a more suitable material to use for your decking subframe.

All our composite decking is installed with a 25-year residential warranty, provided all complies with our installation guidelines. Here at NeoTimber®, sometimes we question why customers would lay our 25-year warranty deck boards onto timber subframes. Even the most carefully laid timber subframes are susceptible to rotting over time. Our plastic lumber subframe alternative won’t suffer from the inevitable weathering damage that timber unfortunately is plagued by.

Low Maintenance.

Although timber remains the most common material for laying a subframe, there is another way. Plastic lumber is an outdoor solution that offers high protection against the elements. A wooden subframe will inevitably rot and warp if not treated correctly, thereby resulting in a damaged deck.

Longevity.

Plastic lumber, like our composite decking, is designed to go the distance and is guaranteed to provide you with a long-life solution that offers ultimate peace of mind. It won’t splinter, it is strong and durable and will never rot or warp due to the damaging effects of moisture.

Installation.

The installation process is simple especially when using our pedestals which are built to work with our plastic lumber. The installation of a plastic lumber subframe is very similar to that of a timber subframe. Solid lumber can be concreted in place, hollow lumber, whilst lighter and easier to handle and install, requires a pre-laid concrete base and can only be used as a packer to build up under boards for levelling out.

Environmentally Friendly.

Our plastic lumber is created using 100% recycled plastic which like the materials used to make our composite decking, would otherwise have ended up in landfill. The fibres are moulded together forming a durable rod. This can be cut to size to create your perfect subframe. Plastic lumber is 100% recyclable meaning there is no waste with off-cuts and, if you ever decide to replace it you are not contributing to landfill.

If you’d like to take a closer look to see just why we’re so in love with it, order some free samples today to check out the quality of NeoTimber’s composite decking and the beautiful colour range we have on offer.

Need Further Support or Advice?

If you’ve still got questions that have not been answered here, or you would like additional advice,

support or assistance then please give one of our friendly experts a call and we’ll be happy to help.

Just give us a call on 01530 382 180.